This page contains affiliate links. This means that we may get a small commission for recommending products, if you choose to click on something and buy it. This does not cost you anything, but we wanted to be honest and let you know!

(Last Updated On: )“There is nothing harder than to make people use a new metal. Luxury items and ornaments cannot be the only sphere of its application. I hope the time will come when aluminum will serve to satisfy daily needs.”

Sainte-Claire Deville – French chemist 1856

Aluminum is part of our everyday life. It is hard to believe that it is one of the newest metals to have been discovered.

The discovery was not made until the 19th century as aluminum does not occur naturally in its purest form.

It took developments in chemistry and the emergence of electricity for this metal to make its debut.

It has been just about one and a half centuries since Aluminum’s advent. Since then, the metal is used in almost every sphere of our daily life.

Taking into account all of the suppliers and related businesses, the aluminum industry drives $174 billion in economic impact.

Table of Contents

Aluminum and the Boating Industry

One of the industries besides airlines that have benefited from aluminum is the boating industry.

The first aluminum hull was built in the 1890s, and the use of this metal has revolutionized today’s boats.

The majority of small personal watercraft and even large shipping vessels have grown and developed innovative products thanks to aluminum.

On some boats, the entire hull is made from aluminum. Other parts and equipment, such as ladders, railings, and gangplanks, are almost exclusively made from the metal.

Aluminum has a variety of characteristics that have made it ideal for marine applications. In many cases, the metal has edged out other materials such as steel or plastic and fiberglass.

Highly shapeable, aluminum lends itself to sculpturing. In this regard, computers have revolutionized the boat building industry.

Hull designs are created with three-dimensional computer-aided design (CAD) software.

The designs can be directed to computer-controlled cutting tables that make quick and uniform cuts. If boats are made in a mold, as a fiberglass boat is, any changes are difficult to make.

Aluminum boats can accept changes in design, and bulkheads can be altered, and cabins resized. Equipment can be relocated easily on aluminum boats by merely cutting and welding and bolting it into position.

A considerable advantage in the boating industry, as it allows for flexibility in design and allows a boat to be customized.

Pure aluminum is very soft, so it is always combined with another metal to make an alloy.

The aluminum used for the boating industry today is a 5xxx series alloy (a metal or metals that are combined with one or more elements) that can be fabricated with the usual shipyard techniques and does not require post-weld heat treatment.

The many benefits of aluminum have contributed to boats made out of aluminum, retaining their value over time.

Advantages of Aluminum In The Boating Industry

Here are a few of the reasons that lay behind the way aluminum has revolutionized the boating industry.

Aluminum is Lightweight

Light and strong, aluminum has increased corrosion resistance and is flexible. The properties of aluminum contribute to it being an ideal metal for boat construction.

Aluminum can be cut with power tools, filed and shaped easily. It is also quicker to weld and fabricate than steel. This advantage translates into both labor and cost savings for the manufacturer.

The lightness of the material translates to cost savings for the owner of an aluminum boat too. Under the same conditions, an aluminum boat will use 20% less fuel than its fiberglass counterpart.

The difference is even more noticeable between steel and aluminum, with a 30% difference in fuel savings between comparable boats.

The reduced weight of aluminum makes for a more fuel-efficient boat. The bigger the boat, the greater the savings.

The lighter weight also means greater speeds for the aluminum boat. An aluminum alloy is a common material for ferries, in which the lightweight of the material translates to faster speeds.

The advantage of lightweight and high speeds has proved valuable for military crafts, patrol boats, hydrofoils, and workboats.

In 1895 a 190-foot torpedo boat, Sokol, was built by a Scottish shipyard, Yarrow & Co., for the Russian navy. Even 125 years ago, the vessel was able to attain a record speed of 32 knots.

September of that same year saw a streamlined mono-hull aluminum yacht, the Defender, win America’s Cup.

At a length of 345 feet, the Hawaii Superferry is a catamaran that can carry 1,000 passengers and 300 vehicles, all while traveling at 30 – 40 knots.

One of the world’s largest aluminum boat hulls at 413 feet, the Benchijigua Express, can go up to 36 knots while carrying 1,350 passengers and 337 vehicles.

Aluminum is Strong

Aluminum’s lightweight would mean nothing if there was no strength to the material. Today’s aluminum alloys have been created to be as strong as steel when it comes to strength to weight ratio.

The three main alloys used as marine grade are 5052, 5083, and 5086. They are produced in rolled sheets plates and primarily used in boat hulls.

Hulls can take quite a pounding in rough seas before they start to deform. The alloy makes the vessel buoyant and less susceptible to sharp dips and turns when in choppy waters.

Tests in seawater have shown that even after ten years of use, the 5xxx series of aluminum alloys have shown a tensile strength reduction of only 2 to 5 percent.

Aluminum is Corrosion Resistant

The corrosion resistance of the 5xxx series alloys is another major factor in the selection of aluminum for marine applications.

Corrosion occurs when there is a chemical interaction between a metal and the environment that the metal is in. The metal can be destroyed as a result of corrosion.

In the case of aluminum and its alloys, they are subject to corrosion when exposed to oxygen and moisture.

It would seem as if those two conditions would make aluminum detrimental as boating material.

However, this versatile metal has a natural oxide film that forms on the surface, and it acts as a protective shield between the metal and the environment.

Even if the surface of aluminum is scratched, a new film of oxide will quickly form. While not wholly immune to corrosion, aluminum and its alloys are corrosion resistant.

96% of all water on the planet is saltwater. The ability of aluminum to resist corrosion has been especially beneficial to the boating industry.

Also, the aluminum industry has continued to work with the marine industry to ensure the strength and corrosion resistance of aluminum through the development of new alloys

Aluminum Needs Less Painting

Except for the area below the waterline or areas where fixtures and fittings touch the hull surface, aluminum hulls do not need painting.

The American Boat and Yacht Council (ABYC) has recommended that “aluminum vessels shall have a protective paint coating that provides a high [electrical] resistance barrier between the aluminum and the water.”

The majority of commercial and military watercraft will leave the aluminum unpainted from the waterline upwards.

Again, this is another considerable labor and cost-saving measure of aluminum that has a positive impact on the boating industry.

Aluminum Boats are Easier to Repair

Unlike fiberglass, steel, or wood, aluminum is relatively easy to repair, and those repairs, when done correctly, are as substantial as the boat was originally.

When an aluminum boat hits an object such as a rock, it tends to dent rather than shatter as fiberglass does.

A dent can usually be pounded out with a hammer. If needed, it can be cut out with a saw and the aluminum replaced.

This video shows how to make a lasting repair on an aluminum boat:

In Conclusion

In the first months after the end of World War II, governments were no longer building fighter planes and bombers. The orders had been canceled, and aluminum manufacturers found themselves with vast quantities of aluminum.

Approaching various other manufacturing industries, the aluminum suppliers were seeking other outlets for their stockpiles.

The boating industry seized on the unexpected availability of inexpensive material. At that time, boats were generally made of wood or steel. The superiority of aluminum was a perfect marriage.

Aluminum boats were light in weight, extremely durable, and proved to be almost maintenance-free.

These attributes contributed to aluminum becoming the new standard in the boating industry. That tremendous impact holds today.

A Few of The Best Aluminum Boat Manufacturers

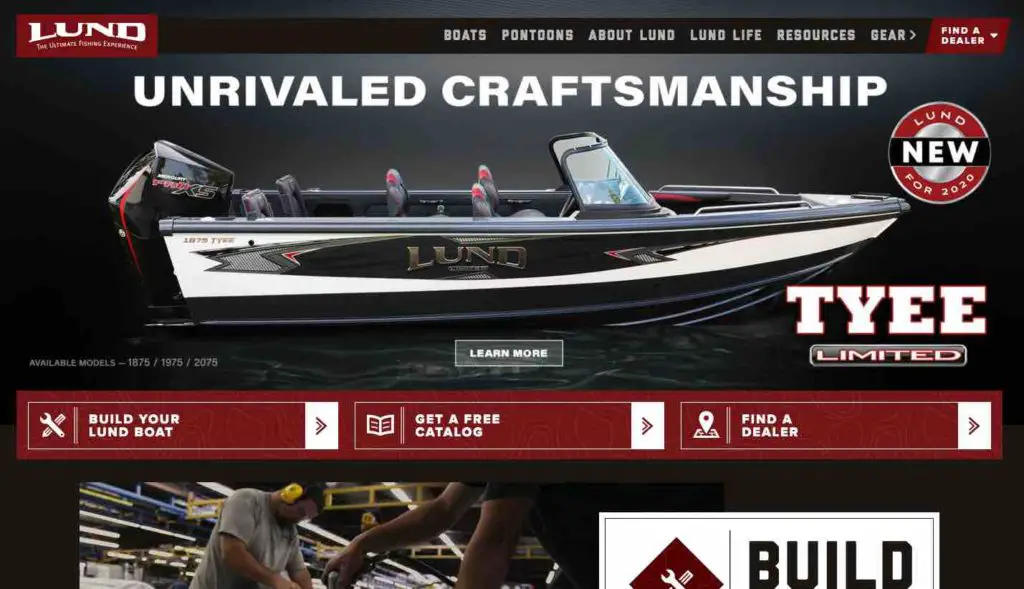

Lund Boats. The Ultimate Fishing Experience

With over 60 years of experience, Lund has been crafting some of the most popular fishing boats in the industry.

Crestliner Aluminum Fishing Boats | Pontoon, Bass, Ski & Jon Boats. Forged With Strength. Defined by Durability

In business since 1946, Crestliner is synonymous with the world’s most durable aluminum boats.

Pontoon Boats & Tritoon Boats by Bennington Marine. Luxury & Performance

Established in 1997, Bennington is a premier luxury pontoon boat manufacturer.

Alumacraft. Family. Fishing. Forever

Alumcraft celebrated its golden anniversary in 1996 and has produced more than half a million boats. It is one of the largest and oldest boat manufacturers in the country.

Xpress Boats – Aluma-Weld. The Original All-Welded High-Performance Aluminum Boat

Family owned and operated, Xpress Boats has been building quality aluminum boats in Arkansas since 1966.

Lowe Boats. Passion. Heritage

Founded in 1971, the co-founder, Diana Lowe, is the daughter of J.B. Appleby. J.B. was considered to be the “father of aluminum boating” in the Lebanon, Missouri area.

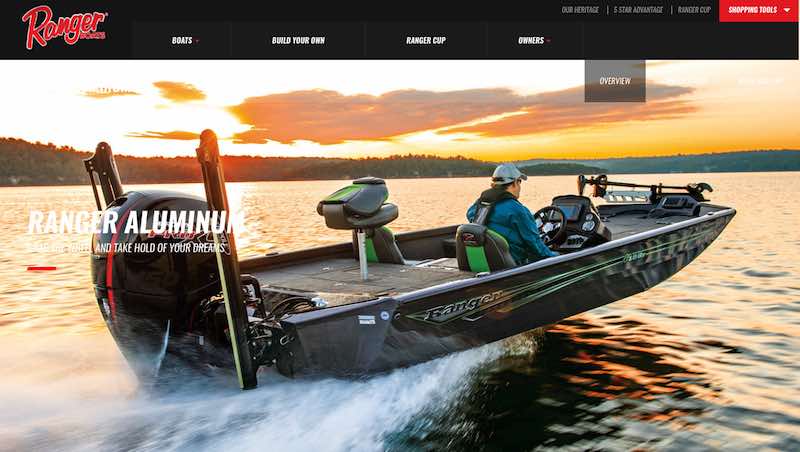

Ranger Aluminum. Proud to be Made in America

In operation over 50 years, Ranger was instrumental in developing U.S. Coast Guard floatation standards by the use of flotation materials.

They also patented the aerated live wells to keep fish alive until release after tournaments.

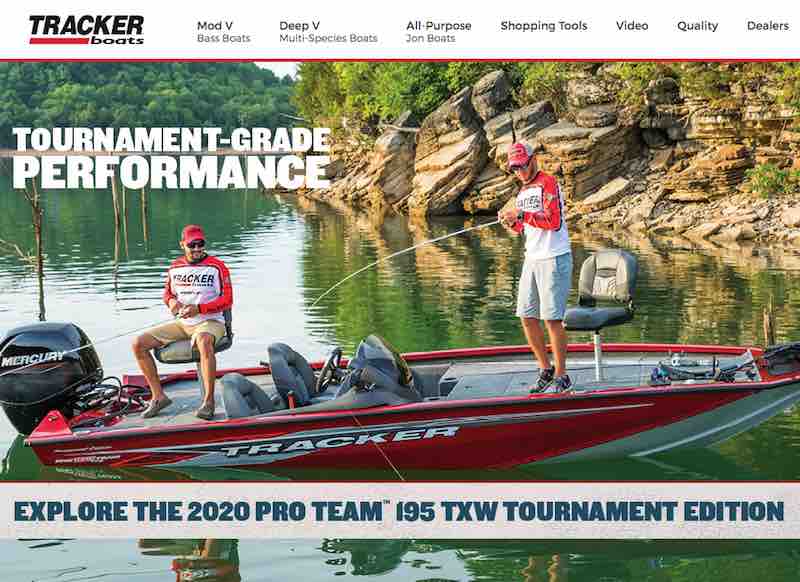

Tracker Boats. It’s More than a Boat. It’s Tracker

In business since 1978, Tracker has remained one of America’s top-selling brands of aluminum fishing boats.

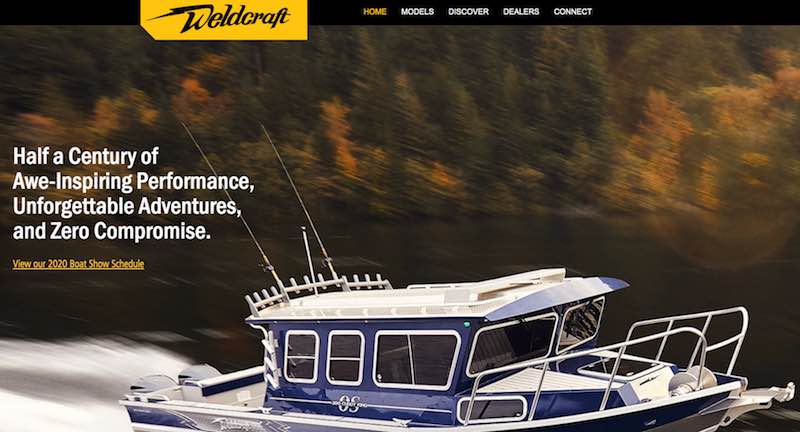

Weldcraft Marine. Designed for Living. Welded for Life

Weldcraft Custom Boats began in 1968 by designing aluminum boats that could withstand the Snake River in Clarkston, Washington. Their goal yet today is building boats to a lifetime standard.

Northwest Boats. Experience the Great Northwest

In business since 1995, Northwest boats use 5086 aluminum alloy along with heavy-gauge welded aluminum for all of their boat bottoms.

FAQ’s

How long will an aluminum boat last?

Of high material strength with excellent corrosion resistance, aluminum boats have exceptional longevity.

Under normal conditions, and with proper care taken, an aluminum boat can easily last 30 to 40 years.

How do you shine aluminum boats?

To put the shine back on an aluminum boat, first, clean the hull with fresh water and wash with a liquid detergent.

Sand the hull with wet sandpaper starting with 200 grit and moving incrementally up to 1000 grit.

Polish with a handheld rotary tool with a felt buffing wheel and shine with a soft cloth once all es of polish has been removed.

Do aluminum boats get hot?

Yes, aluminum boats will transfer heat quickly. Once the boat is in the water, it will cool to the temperature of the water. An aluminum boat will be cold in the wintertime.

How thick is an aluminum boat?

Generally speaking, an aluminum skiff will be about ⅛ inch, which is a thickness that can be readily welded. Larger boats will use aluminum that is about 3/16 to ¼ of an inch thick.

What spray paint is suitable for aluminum?

As the surface of aluminum is slick, rough the surface up first with sandpaper. You must use an acid-etch primer before applying the paint color of your choice. There are several brands of primer and paint for aluminum on the market, including Rustoleum.

What is the strongest adhesive for aluminum?

Epoxy adhesives are the best for bonding aluminum to other metals. Choose an epoxy, such as Permabond, that will allow for expansion and contraction.

Can you JB weld aluminum to steel?

Steel cannot be welded to aluminum by the layman using JB Weld, or any other on the market adhesives. There are a few specialized processes, such as ultrasonic welding, but as a general rule, it is not possible.

What material are boats made of, in general?

Today’s boats are made of wood, steel, aluminum, or fiberglass or any combination of these various materials.

Fiberglass is typically for recreational watercraft, and steel is for large vessels, wood and aluminum are found on canoes, skiffs and fishing boats as well as pleasure crafts.

What is the best aluminum fishing boat?

Per Boats.com, the top five aluminum fishing boats are Crestliner 1750 Fish Hawk, Kingfisher 2025 Flex Tiller, Lowe 1810 Fishing Machine, Princecraft 195 Xperience, and the Lund 1775 Crossover.

Fun Facts

Aluminum

In the periodic table, the symbol of aluminum is Al. The atomic weight is 26.981. The atomic number is 13. It is classified as a post-transition metal.

This Should Quench Your Thirst

An interesting statistic is that the world’s beer and soda industries use about 200 billion cans every year.

Breaking that down, that is 6,700 aluminum cans every second; enough to go around the planet every 17 hours!

Aluminum is 100% Recyclable

This is a fascinating video from Discovery answering the question:

The Dinnerware of Presidents

Aluminum is the choice of presidents! Interestingly enough, rank and file guests at state dinners for Napoleon III, the first president of the French Republic, were served on dishes made of gold or silver. Important personages were served on aluminum.

The Great Depression

During the Great Depression, the government instituted the Works Progress Administration (WPA) hydroelectric projects.

These projects were instrumental in developing the electrical capacity that was needed for industrial- class aluminum production.

The Aluminum Association is Founded

October 1935 saw the first-ever meeting of The Aluminum Association held in New York City.

It Can Fly

A standard Boeing 747 contains 147,00 pounds of aluminum.

Aluminum On The Moon

From the Wright brothers to Sputnik to the Apollo Space Program, aluminum has been essential to all of the significant advances that have been made in aerospace accomplishments.

It Won’t Tell You Which Way Is North

Aluminum is non-magnetic, which is a great advantage when using other metals around it.

It Is Under Your Feet

Aluminum is placed in the third position of the most abundant element in the earth’s crust. It is often found in compounds or minerals.

What Goes Around Comes Around

According to the Aluminum Association, about 75% of all the aluminum ever made is still in use today, thanks to recycling.

World’s Largest Aluminum Yacht

Dutch builder, Royal Huisman, has debuted a 266-foot schooner, Sea Eagle II. Commissioned by Dr. Samuel Yin, the 13-foot rudder is the largest ever to be crafted out of carbon composite.

The schooner will accommodate 12 guests and 13 crew members. Perhaps the most fascinating item onboard is the hydraulic crow’s nest, which is sure to afford the best seat on the boat.

Other Items Made From Aluminum

There is a myriad of items made from aluminum. Some of the items are airplanes, utensils, foil, mailboxes, nails, ladders, computer parts, staples, golf clubs, bike frames, car rims, pots and pans, patio furniture, fencing, faucets, window frames, sinks, gates, screen doors, antennas, wiring, sports equipment, car parts, cans, lids on yogurt, space shuttles, power lines, laptops, iPads, and iPhones to name a few items.